Position:

Home

> PRODUCTS

> Film Faced Plywood

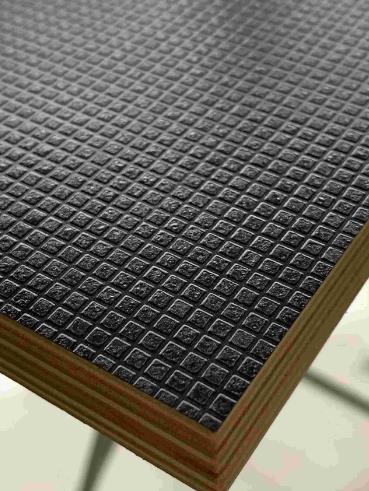

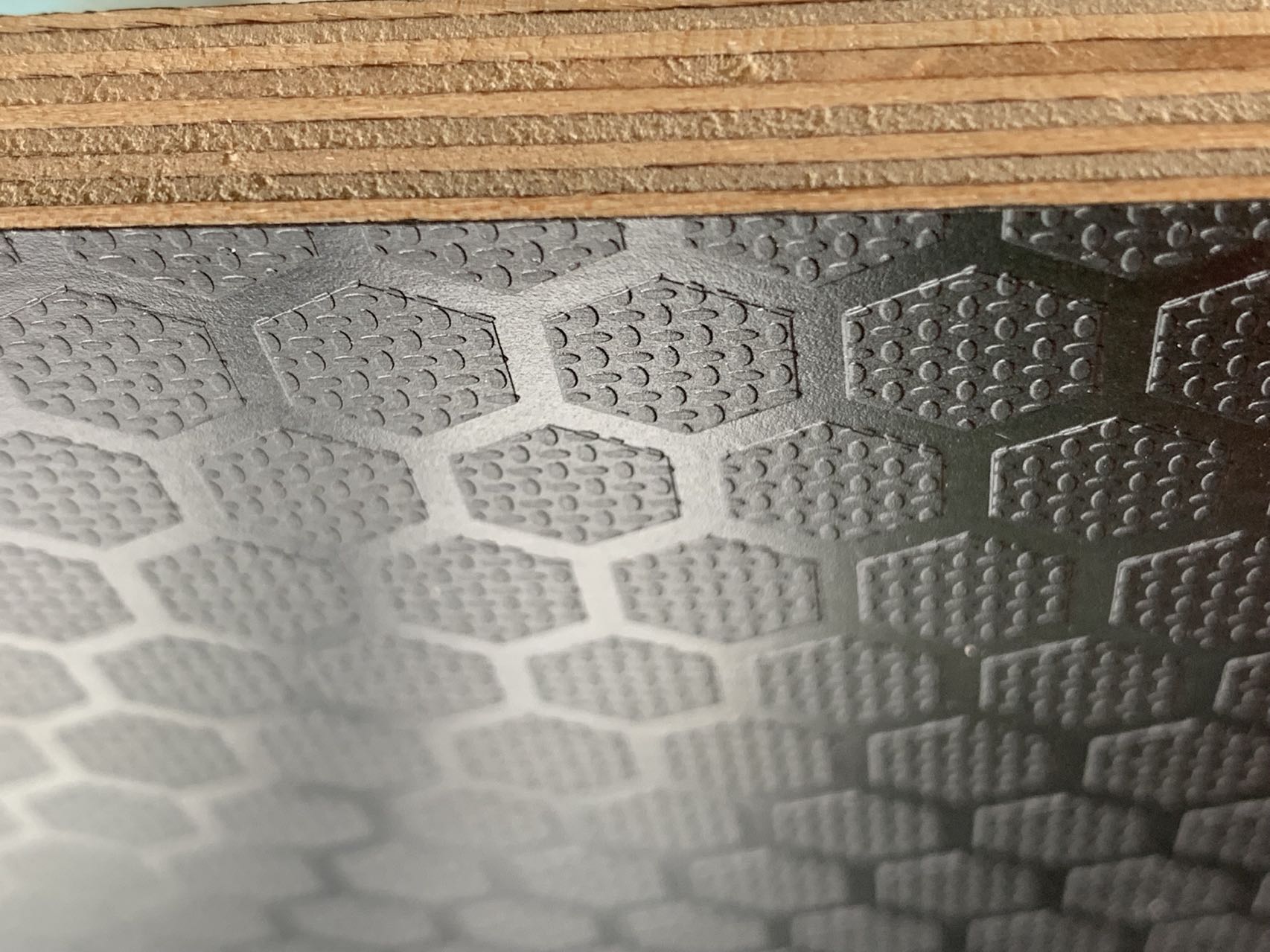

Non-slip surface Film faced plywood

发布时间:2019-09-27 浏览次数:2628

Product | Film faced Plywood | Species | Birch | |||

Film: | Non-slip surface | Grammage: | 180g/㎡ | |||

Size: | 18mmx1220x2440 BROWN | Glue: | WBP:Melamine/Phenolic | |||

Sr. | Property | Unit | Test | Value of | Result | |

⒈ | Moisture Content | % | EN 322 | 10% | Check out | |

⒉ | Density | kg/cbm | EN 323 | 580 | Check out | |

⒊ | Bonding | Bonding | Mpa | EN 314 | Max: 1.37 | Check out |

Min: 0.65 | ||||||

Damage Rate | % | ----- | 65% | |||

⒋ | Bending | Longitudinal | Mpa | EN 310 | 6800 | Check out |

Lateral | 5200 | |||||

⒌ | Bending | Longitudinal | Mpa | 48.3 | Check out | |

Strength | ||||||

N/mm | Lateral | 35.7 | ||||

⒍ | Cycle Life | About12~15 Repeated Using times According | ||||

Projectes by formwork Application | ||||||